Innovative, certified technology for worldwide use

MANGOLDT develops, designs and manufactures application-specific chokes with iron cores or air cores that ensure maximum safety and efficiency in electrical networks all over the world.

Our customized solutions are the benchmark in numerous sectors of the electrical industry.

Our products

MANGOLDT has been producing components for use in electrical engineering since the company was founded in 1941. Today, with sites in Germany, East Asia and India, we are operating worldwide on a sustainable growth path.

A real plus for our clients - from international market leaders to highly specialized technology companies and service providers to energy suppliers.

With them, we rely on long-term business partnerships and joint entrepreneurial success. The key to this is the outstanding quality and lasting performance of our certified products - as well as the high level of expertise of our employees in technology and consulting.

Filter Chokes

Filter chokes protect reactive current compensation systems against overloads caused by interference levels in medium and low voltage networks.

MANGOLDT filter chokes are available for low and medium voltages as single-phase or three-phase iron-core chokes for detuned and tuned filter circuits. Depending on requirements and ambient conditions, the design is adapted to all customer wishes - from winding the coils with copper wire, copper or aluminum strip to temperature monitoring. On request, a type test with heat run in accordance with IEC 60076 under real conditions or a partial discharge test can be carried out.

Our filter chokes also feature the PolyGap® design. This and an elaborate vacuum pressure impregnation ensure that noise emissions are minimized.

For use in North America, MANGOLDT filter chokes are also available with the necessary test marks in accordance with UL guidelines.

Line Chokes

MANGOLDT offers a standard product line of line chokes for use in speed-controlled drive applications that ensure trouble-free operation of your system.

As a reliable basic solution for current, voltage and frequency converters, line chokes reduce the feedback effects of powerful electrical drives and systems on the upstream power grid. They increase the mains impedance in such a way that the interference caused by the functional commutation of motors and cables is efficiently reduced.

The impedance increase by a mains choke also limits starting and peak currents when power converters are switched on, thus protecting their electronics. In addition, charging peaks on the DC link capacitors are also attenuated.

MANGOLDT's standard product range offers every line choke with impedance values from 3% to 5% and is available from stock. This means that over 100 different products are available for shipment from Germany, Taiwan, USA and Canada.

MANGOLDT supplies all line chokes as standard in accordance with UL guidelines with the required test marks.

Compensating Chokes

In industrial plants, compensation systems reduce unwanted reactive power. Compensating chokes are an essential component here, which - connected in series with a capacitor - generate inductive reactive power to compensate for cable or network capacities.

MANGOLDT compensating chokes are available in single-phase and three-phase versions for applications in low-voltage and medium-voltage networks up to a mains voltage of 36 kV. The durable, very precise chokes make every compensation system a reliable cost saver.

For use in North America, the low-voltage versions of MANGOLDT compensating chokes are also available with the necessary test marks in accordance with UL guidelines.

Air Core Chokes

Air core chokes have a core made of air or non-ferrous or non-conductive material. This makes them ideal for very high frequencies. Free of ferromagnetic material, they avoid saturation, eddy current losses and hysteresis losses.

Air core chokes from MANGOLDT effectively limit switching peaks and inrush currents in compensation systems. Optimally designed for the rated current and the load conditions of capacitors, the chokes dampen the incoming currents in such a way that the internal linings and connections are reliably protected.

As current limiting chokes, MANGOLDT air core chokes are primarily used to limit short-circuit currents in downstream power supply units. As a result, the switching devices, cables and other elements present here can be designed for a significantly lower short-circuit power.

Smoothing Chokes

Smoothing chokes ensure the reliable functioning of starting converters in power electronic systems that switch very high loads of up to 12 MW for short periods. Thanks to their inductivity, they generate a smooth, harmonious rise and fall in currents. In this way, they reliably prevent circuit-related current gaps and failures in highly safety-relevant systems that would be caused by sudden changes in current.

MANGOLDT smoothing chokes are used worldwide in power plants or large production facilities where one hundred percent long-term functional reliability is required. Each of the components, which can weigh up to 5 tons, is designed to be application-optimized and its inductance curve is precisely measured before delivery. This protects users from expensive failures and repairs in the long term.

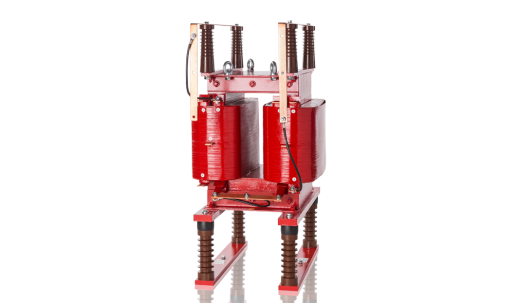

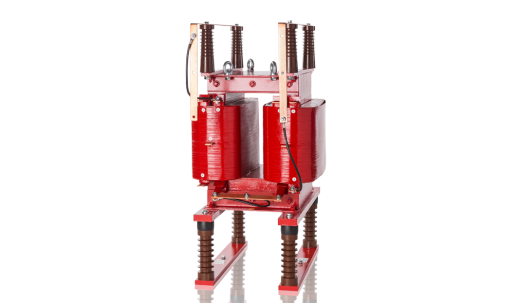

Audio Frequency Blocking Devices

To prevent control signals transmitted by audio frequency transmitters via the power supply network from flowing into power factor correction systems and charging their capacitors, these are blocked by audio frequency blocking devices.

MANGOLDT audio frequency blocking devices are dimensioned exactly to the power of the downstream system and tuned with high precision to the respective audio frequency of the control signal. They generate a very high impedance exclusively at this defined frequency. This makes them a reliable barrier for the control signals and at the same time allows all currents with mains frequency to pass through almost loss-free.

The systems for low or medium voltages are also available in application-specific variants.

Tuning Inductors

In audio frequency transmission systems for the transmission of control signals via the power supply network, tuning inductors play a decisive role in signal quality and the efficiency of such ripple control systems. A very high quality is crucial, especially in the transmission frequency range.

MANGOLDT tuning inductors are integrated into ripple control systems as part of a rigid coupling. Their different taps allow different assignments in order to set the inductance quickly and with high precision. This makes it easy to compensate for the design-related tolerances of capacitors. It also enables operators to react cost-effectively at any time to capacitance changes in the capacitor due to ageing effects.

As a positive additional effect, the minimal power loss of the coils reduces the required transmission energy of the system and thus saves energy costs.

Transformers

Our low-voltage transformers adapt the voltage level to the connected low-voltage grid and ensure galvanic isolation, which protects electrical components from lightning strikes, for example, by decoupling the circuit. They work in local distribution grids and ensure that industry, commercial areas and residential areas are supplied efficiently and safely with the correct voltage.

Custom-made transformers from MANGOLDT for applications in power distribution, electrical drives and renewable energies, such as our inverter transformers for mobile battery storage systems, offer the optimum solution for your application.

Choose us to power your application safely and efficiently. Our commitment to excellence ensures that every custom transformer we build for your application is designed for reliability, longevity and optimal performance.

Sinusoidal filter chokes

In very interference-sensitive or highly safety-relevant environments, the rectangular pulses of the output voltage of inverters have a major negative impact. Sinusoidal filter chokes generate a sinusoidal voltage curve effectively and almost loss-free without voltage overshoots and with flat rises in the curve.

In addition to machines and systems, sinusoidal filter chokes also protect the grid from the feedback effects of the frequency converter. They increase the efficiency and service life of motors, ensure lower noise emissions and prevent interference emissions from the motor cable.

For use in North America, MANGOLDT sinusoidal filter chokes are also available with the necessary test marks in accordance with UL guidelines.

Indirectly Water-Cooled Chokes

MANGOLDT technology proves its reliable performance day after day in numerous industrial applications. Our customers from a wide range of sectors in the electrical industry rely on MANGOLDT's innovation, especially for specific products - including our water-cooled solutions.

The indirect water-cooled solutions from MANGOLDT are very compact and extremely powerful. Losses are almost completely dissipated via the cooling circuit, which means that the power density in the control cabinet can be increased. This is achieved thanks to the very high heat absorption capacity of water and the targeted cooling of individual elements.

The volume of the components can be significantly reduced, as fans can be made smaller or eliminated altogether. The result: positive effects for performance, efficiency and service life.

For safety-relevant special parts, such as connections for cooling water, MANGOLDT uses materials with special properties as standard to ensure long durability and corrosion resistance. This ensures that the safety criteria for indirect water-cooled solutions can be met perfectly. MANGOLDT therefore trusts in the reliable tightness of the all-metal connections made of stainless steel, aluminum or brass.

Thanks to special push-in fittings, MANGOLDT enables its customers to make very simple cooling water connections, making installation quicker and safer. At pressures from -0.95 to +16 bar and temperatures from -40 to +120° C, the chokes always work reliably, even in the harshest environmental conditions.

Customer-Specific Solutions

With highly specific custom-made products, we also implement solutions for our customers whose individual design is at an even more specialized level than our tailor-made chokes for standard applications.

MANGOLDT's specialist knowledge and the consulting expertise and experience of our technical sales team are crucial to the reliable quality of all custom-made products. With their deep understanding of the production and application of electrical chokes, our engineers develop a tailor-made solution for every requirement and answer all questions relating to this complex topic, especially in high voltage ranges.

The basis for innovative results with added value is a modern production environment with computer-aided design at the production site and company headquarters in Aachen. Here, all custom-made products - as well as all other chokes - are put through their paces using certified testing technology. This is how we guarantee one hundred percent functionality.

Sine Wave Filter

MANGOLDT's PSF type sine wave filters set a new standard for sine wave filter performance and reliability. The combination of precise three-phase chokes and high-performance capacitors guarantees first-class motor protection and extended motor life.

Based on the knowledge gained from several decades of application experience and ongoing research and development, they offer stable properties for your application. The PolyGap® core technology is used for low power losses and balanced inductance. This results in a longer service life for MANGOLDT PSF sine wave filters.

Sine filters from MANGOLDT are designed to be suitable for both the mains input and the load output of drive systems. The modular design and compact dimensions allow easy integration and installation. They are designed for higher DC link voltages to ensure proper function even in stressful applications such as active front-end drives (AFE) and motors for frequent regenerative braking.

MANGOLDT supplies all sine wave filters as standard in accordance with UL guidelines with the required test marks.

MANGOLDT's success is based on the expertise, consulting strength and enthusiasm of our entire team. With great commitment, we create high-performance products of optimum quality for our customers worldwide.

Hans von Mangoldt GmbH

Hergelsbendenstraße 18

D - 52080 Aachen

+49 241 16607 -0

info@mangoldt.com